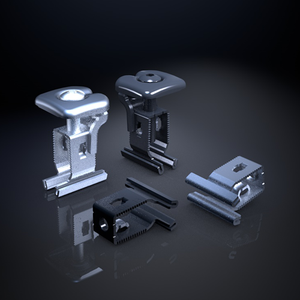

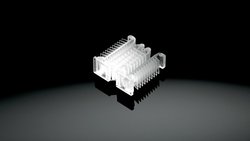

MATERIAL STEEL

MATERIAL STEEL

The right material for your application: galvanized, high-strength steel, micro-alloyed multiphase steel, carbon steel (hardened and galvanized), stainless steel or designs with black surface.

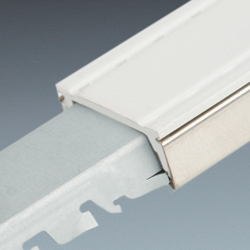

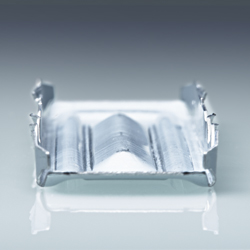

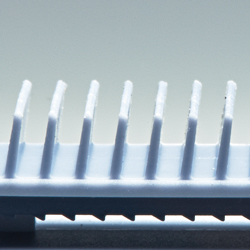

SERRATED EDGES

SERRATED EDGES

A variety of designs are available – with staggered heights – for easy insertion and a secure, durable grip in the profile.

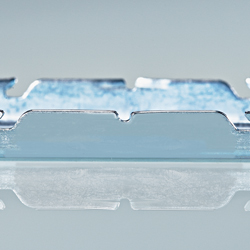

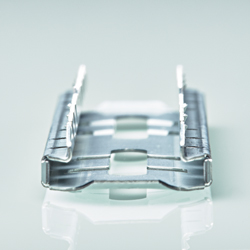

U-SHAPE

U-SHAPE

A fast and secure filling of the hollow spacer bar is an absolute must for the efficient manufacture of the insulating glass unit. This is where the thin-walled materials of the EK STEEL Connect straight connectors prove their worth and ensure a smooth production process.

CENTERING

CENTERING

Provides a 50/50 positioning of the connecting element at the junction point and thus optimum performance. Centering ensures the connector sits precisely in the middle of the profile connection and pushing it in too far is prevented. Several versions are available – we choose the most appropriate design for the application in question.

3 SIDE SEALING

3 SIDE SEALING

Dust-tight seal on the inner contour of the profile to the space between the panes and the butyl section along the edges: optimal positioning of the connecting element provides a perfect fit and tight profile connection. Release of dust or molecular sieve material into the space between the panes is prevented.

DURABLE SPACER/FRAME CONNECTION

DURABLE SPACER/FRAME CONNECTION

Prevents the frame from opening during subsequent handling and ensures a long life cycle for the insulating glass unit.

SEAM

SEAM

Demands placed on the connecting element are very high, especially for thin-walled profiles. The optimised design of the central rib increases the stability and loading capacity of the insulating glass unit.

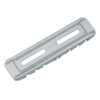

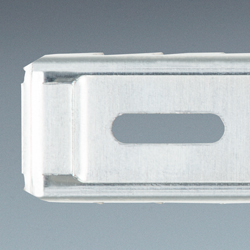

SLOTS

SLOTS

Provide an optional connection for Georgian bars at the junction point. The middle section is closed to prevent dust or molecular sieve material penetrating into the space between the panes. The slots permit a fastener (pin, screw) to be used to secure the Georgian bars while maintaining stability.

GRIP SUPPORT

GRIP SUPPORT

Ensures a strong grip of the connecting element and thus a high load capacity of the junction point even for large and heavy insulating glass units.

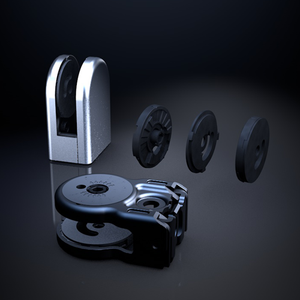

BACK PLATE

BACK PLATE

To increase stability and (as a tube-in-tube system) for sealing the spine of the profile. Adjusted to fit our connectors and delivered as a single unit, which can easily be filled with desiccant.

BUTYL APPLICATION

BUTYL APPLICATION

To achieve a gas-tight unit, butyl is applied to the back plate of the straight connector. This provides a reliable seal along the spine of the profile and the adjacent side walls at the junction point.

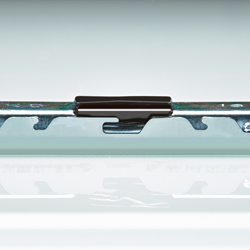

SPRING TONGUE

SPRING TONGUE

To provide a secure grip and prevent possible removal. When used with a straight connector, the spring tongue hooks into the perforation of the profile. In the case of the corner key or model corner, the tongue provides a tight seal and permanent grip within the spacer.

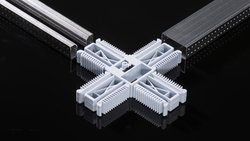

MATERIAL POLO

MATERIAL POLO

Whether polyamide (PA) is used with different amounts of fibre glass (M = medium, H = hard, XH = extra hard) or anti-fog polypropylene (PP), in particular for our press-on and screw-on end pieces – we choose the best material with the highest quality.

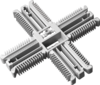

LAMELLAS

LAMELLAS

To provide a secure grip in the perforation and to hold straight connectors, corner keys and model corners, end pieces and cross connectors in position. Lamellas prevent possible removal and compensate for any profile irregularities.

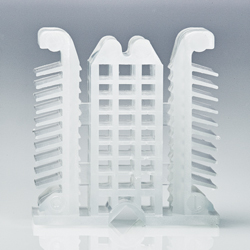

3 COLUMN DESIGN

3 COLUMN DESIGN

The 3 column design of our Georgian bar cross connectors and end pieces increases stability and grip and enables Vienna Georgian bars (box profile) and numerous standard and warm edge spacers to be used for universal application.

ANTI RATTLE SYSTEM

ANTI RATTLE SYSTEM

As a result of their bellows-type design, EK Georgian bar cross connectors provide a permanent grip between the panes and thus prevent movements and rattling in the installed units – without damaging the coating on the panes.